Cavitation technologies

E-PIC S.r.l. has developed different hydrodynamic cavitational elements, which fit for different process needs:

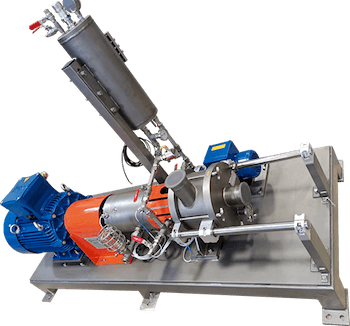

ROTOCAV: dynamic hydrodynamic cavitator, inline installation

CAVIBATCH: dynamic hydrodynamic cavitator, installation in tank

STATICAV: hydrodynamic cavitator

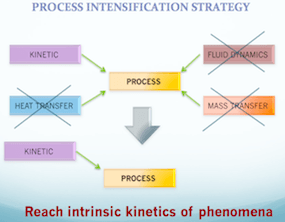

Cavitation is related to formation and rapid collapse of vapor and gas bubbles in a liquid medium: this phenomenon is usually unwanted, as these rapid collapses generate extremely high local pressure and temperature, causing the damage of metal surfaces.

However, if it is generated and controlled on purpose, some processes can take advantages of these local high temperature and pressure. Controlled cavitation can be generated by different methods:

- In hydrodynamic cavitation the liquid is forced to pass in one or more cavitational elements, which can be fixed or dynamic and of particular geometries to maximize the cavitational yeld, in which bubbles are generated and they subsequently implode in a confined chamber.

- In acoustic cavitation bubbles are generated by ultrasound waves and they expand and collapse because of the sinusoidal wave acting directly on the fluid.

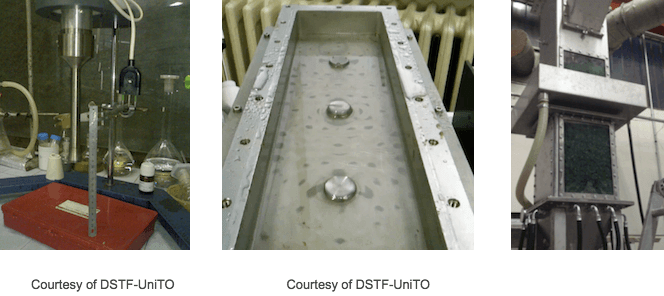

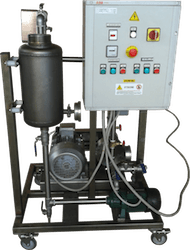

E-PIC S.r.l. licenses proprietary technology and know-how in hydrodynamic cavitation. Moreover, it operates several cavitational technologies, LAB SCALE, BENCH SCALE UNITS and PILOT PLANTS to generate and control this phenomenon.

E-PIC S.r.l. has developed a new innovative hydrodynamic cavitator (ROTOCAV), which can be installed for different applications and in different fields: download the ROTOCAV flyer, the ROTOCAV brochure and the ROTOCAV technical brochure.

Visit our ROTOCAV image gallery to see pictures of our ROTOCAV hydrodynamic cavitators.

E-PIC S.r.l. has developed also static cavitational elements (STATICAV), simple devices to be installed inline: the working principle is to pump the fluid or suspension through the cavitational element at a pressure high enough to generate controlled cavitation.

The treatment is able to generate shear stresses, turbulence and controlled cavitation, resulting in micromixing and particles disintegration.

Main advantages of using a STATICAV cavitational element include low maintenance, low cost and small footprint.

Download our STATICAV datasheet for more info.

STATICAV: static hydrodynamic cavitator, inline installation

CAVITATION can be successfully applied in different fields: